COSMOSIL Packing Material

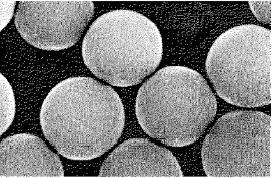

Figure. Microscopic photograph of

the silica gel

Superior HPLC columns can be produced only with excellent packing materials and superb packing technique. COSMOSIL columns are well known for their high efficiency and high-resolution separations. Based on spherical, totally porous silica, COSMOSIL columns provide enhanced chemical and mechanical stability as well as very high surface coverage. The selection of the C18chemistries available enables the chromatographer to tailor separation to special applications. The ultra pure silica based MS-II series with widely extended pH range are developed for improved separation of basic compounds. The C18AR-II phase provides increased acid resistance. Four unique bonded chemistries are available for Cosmosil specialty columns: Cholester, πNAP, PYE and HILIC. These specialty columns may improve the separation compared with conventional columns. Five highly effective phases for fullerene separation are also available: Buckyprep, Buckyprep-M, PBB, PYE and NPE. COSMOGEL packing materials are non-silica based and provide superior performance in ion exchange columns.

Raw Material Silica Gel

COMSOSIL is based on ultra pure porous spherical silica gel (purity: 99.99% or higher). Low-purity silica gel contains metal impurity which may cause interference in the separation, especially for metal coordination compounds.

| Condition | |

|---|---|

| Column Size | 4.6 mm I.D. x 150 mm |

| Mobile Phase | Acetonitrile : Water = 50 : 50 |

| Flow Rate | 1.0 ml/min |

| Temperature | 30 °C |

| Detection | UV 254 nm |

| Sample | Paeonol |

Stationary Phase Construction

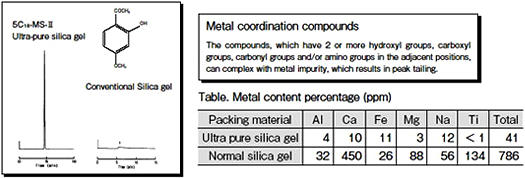

While C18 columns are most widely used in reversed phase HPLC, it is important to distinguish between two very different bonded phase formats. Monomeric type C18 format incorporates the bonding of the C18 alkyl chain to a single silica atom on the silica gel backbone. Monomeric type columns such as the COSMOSIL C18-MS-II and the MS series have excellent synthesis reproducibility, very good lot-to-lot reproducibility and short mobile phase equilibration times. On the other hand, the polymeric C18 format incorporates a tri-functional silylation procedure whereby the octadecyl group is bonded to 2 or 3 silica atoms on the silica gel backbone. This increases silylation results in far greater column stability particularly in acidic mobile phase conditions. Stereo recognition capability is also greater than that of the monofunctional silylation type C18 columns. The polymeric format is offered in the AR-II and the entire AR-300 series of COSMOSIL columns. Please refer to product descriptions and application chromatograms for selection guidance.

Figure. Diagrams of different stationary phase constructions (before end-capping treatment)

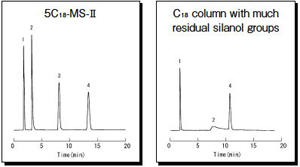

End-capping Treatment

The silanols (Si-OH groups) on the silica surface provided bonding site for stationary phases. However, part of the silanol groups remain un-capped as residual silanol groups even after the end-capping treatment, they cause peak tailing for basic compounds. COSMOSIL packing materials for reversed phase chromatography are of near-perfectly end-capped residual silanol groups.

R-NH+ (Basic compounds)

Si-O- (Free sianol group)

Basic compound can form ionic bonds with residual free silanols. The ionic bonding causes peak tailing of basic compounds if a silicabased column is not perfectly end-capped.

| Condition | ||

|---|---|---|

| Column Size | 4.6 mm I.D. x 150 mm |  |

| Mobile Phase | Methanol : 20 mmol/l Phosphate Buffer (pH7) = 20 : 80 | |

| Flow Rate | 1.0 ml/min | |

| Temperature | 30 °C | |

| Detection | UV 254 nm (0.16 AUFS) | |

| Sample |

|

|

Synthesis Reproducibility

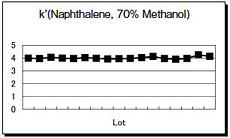

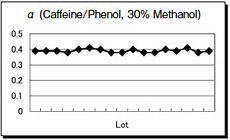

By using strictly selected silica gel and constant synthesis conditions, the chemically bonded type column retains a variance of the capacity factor (k') between synthetic lots of within ±10% and a variance of the separation factor (α) of within ± 5%. The figures below show in graphic form the lot inspection results of synthesized packing material (COSMOSIL 5C18-MS-II). Figure 1 shows the variance of stationary phase (octadecyl group) introduced volume which is the basic indicator of the quality of the packing material. Figure 2 shows the end-capping efficiency of the packing material. The variance among the lots is reduced to the minimum in the COSMOSIL packed columns

k'Nap=k'value of Naphthalene in the 70% methanol

Figure 1. Variance of the combining volume between silica gel and C18.

α C/P=k'(Caffeine)/k'(Phenol) in 30% methanol.

Figure 2. Variance of end-capping efficiency of the packing material.